To reduce the processing difficulty of aluminum nitride ceramics, it is necessary to combine their high hardness and brittleness characteristics, and systematically optimize the material preparation, processing technology, and equipment tools. Specific measures can be taken from the following aspects:

1. Optimize material pretreatment and forming process

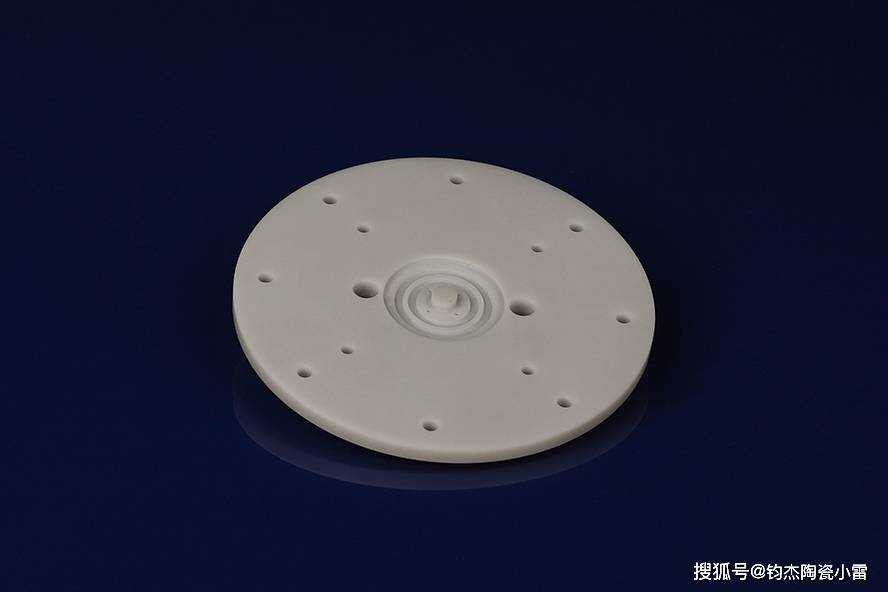

Near net forming to reduce machining allowance * *: prepare blanks close to the final size directly through injection molding, gel injection molding and other technologies, and control the subsequent machining allowance within 0.1-0.5mm. For example, in the production of electrostatic suction cups, the main structure is first formed by pressing the mold, and only the suction surface needs to be finely ground, greatly reducing the cutting amount.

Regulating microstructure: Controlling grain size (such as refining to 2-5 μ m) and reducing porosity during sintering can reduce material brittleness. Adding a small amount of sintering aids such as yttrium oxide can not only increase density, but also improve fracture toughness during processing and reduce the risk of edge breakage.

jrhz.info

2. Adopting adaptive processing techniques and tools

Selection of superhard tools and composite processing: diamond tools are dominant, such as using ultra-fine diamond grinding wheels (particle size above 8000 #) for precision grinding, combined with cooling systems to reduce frictional heat; For complex structures, a combination of "laser cutting+ultrasonic processing" is used - laser rapid prototyping of contours, ultrasonic refinement of details (such as irregular grooves), to reduce cracks caused by mechanical stress.

3. Introducing high-precision CNC equipment: using a five axis linkage machining center, with a combined force feedback system to adjust cutting parameters in real time (such as feed rate 5-10mm/min, cutting depth<0.01mm), to avoid overload and fracture. For micro hole processing, ultra-high pressure water jet (pressure>300MPa) combined with abrasive is used, which improves drilling efficiency by 30% compared to traditional drilling methods.

4. Control machining accuracy in stages

Rough machining stage: Quickly remove excess materials, prioritize efficiency, allow for larger tolerances (such as ± 0.1mm), and avoid stress accumulation due to excessive machining.

Semi precision machining and finishing stage: gradually improve accuracy, achieve micrometer level tolerance through step-by-step grinding (such as removing surface damage layer first, then precision grinding flatness) and multiple inspections (such as real-time monitoring of straightness using laser interferometer). For example, when processing ceramic shafts, first turn them to near tolerance (± 0.01mm), and then refine them to an outer diameter tolerance of 2 μ m using a centerless grinder.

Although these methods cannot completely eliminate the processing challenges brought by high hardness, they can significantly reduce scrap rates and improve efficiency, making aluminum nitride ceramics more suitable for the precision manufacturing needs of semiconductor equipment.