Intoday’sinterconnectedmanufacturinglandscape,OEMCNCmachiningserviceshaveexpandedtheirreachbeyondregionalboundaries,enablingcompaniesworldwidetoaccesshigh-precisioncomponentstailoredtodiverseindustries.Thisglobalexpansionisdrivenbyadvancementsinmachiningtechnology,increaseddemandforcustomizedparts,andtheneedforefficientsupplychains.OEMCNCmachiningprovidersnowserveclientsacrossNorthAmerica,Europe,Asia,andothercontinents,supportingsectorssuchasautomotive,aerospace,electronics,andindustrialmachinery.Theseservicesfacilitaterapidprototyping,small-batchproduction,andlarge-scalemanufacturing,oftenatcompetitivecostsduetoglobalsourcingandautomation.Companiesleveragetheseservicestoreduceleadtimes,improveproductquality,andstayagileincompetitivemarkets.ThisarticleexploreshowOEMCNCmachiningserviceshaveachievedextensiveglobalreachthroughpracticalapplicationsandcasestudies,highlightingtheimpactonvariousindustriesandbusinessmodels.Byexaminingreal-worldscenarios,wecanbetterunderstandthescope,capabilities,andstrategicimportanceofOEMCNCservicesintoday’smanufacturingecosystem.

OEMCNCmachiningserviceshavebecomeanintegralpartofglobalmanufacturing,enablingseamlessproductionandsupplychainintegrationacrosscontinents.Onenotableexampleistheaerospaceindustry,wherecomplex,precisecomponentsarerequiredtomeetstrictsafetyandperformancestandards.AnaerospacemanufacturerinEuropepartneredwithanOEMCNCmachiningproviderinAsiatoproduceturbineblades.Theprojectinvolvedmachiningintricategeometriesfromsuperalloyswithtoleranceswithinafewmicrons.TheAsianfacility,equippedwithadvancedmulti-axisCNCmachinesandautomation,managedtodeliverthepartswithinafractionofthetimeandcostcomparedtotraditionallocalsuppliers.ThiscollaborationexemplifieshowOEMCNCservicescanbridgegeographicgaps,providinghigh-qualitycomponentsontimeandatacompetitiveprice,whichiscrucialforaerospacecompaniesaimingtomaintainglobalsupplychains.

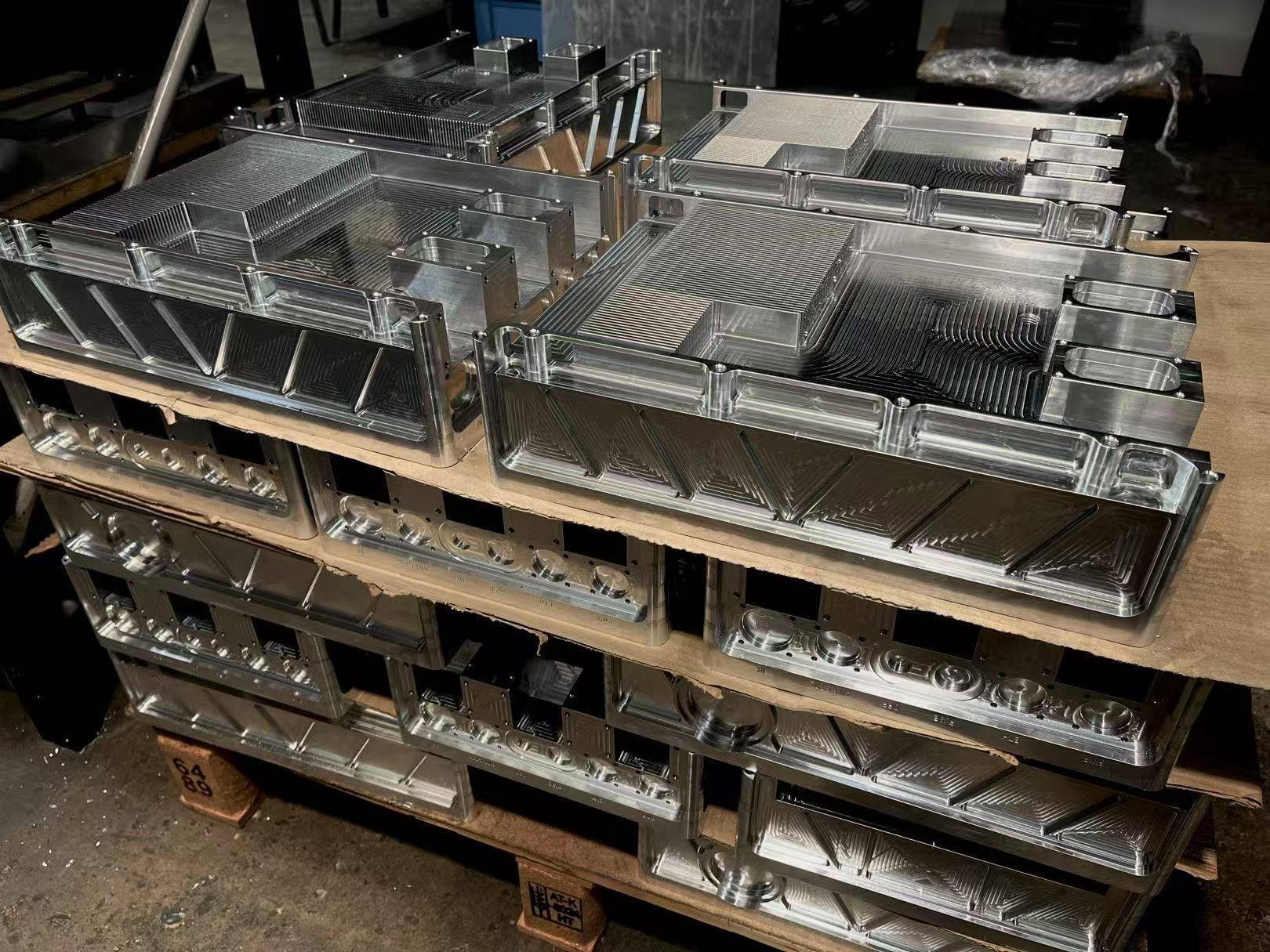

Intheautomotivesector,OEMCNCmachiningserviceshaveplayedapivotalroleinsupportingrapidinnovationandcustomization.ANorthAmericanelectricvehiclemanufacturerrequiredprecision-machinedaluminumpartsforitsbatterymodules.ByoutsourcingtoanOEMCNCproviderinSoutheastAsia,thecompanybenefitedfromlowerlaborcostsandaccesstoadvancedmachiningtechnology,suchashigh-speedCNClathesandmillingcenters.Theprovider’sabilitytohandlesmallbatchrunswithquickturnaroundtimesenabledtheautomakertoiteratedesignsswiftlyandbringnewmodelstomarketfaster.ThiscasehighlightshowOEMCNCservicesfacilitateflexible,cost-effectiveproductionthatalignswiththefast-paceddemandsofautomotiveinnovationandglobaldistribution.

ElectronicsmanufacturingoffersanothercompellingscenariowhereOEMCNCmachiningservicesextendtheirglobalreach.AEuropeanconsumerelectronicscompanyneededsmall,intricatecomponentsforitssmartdevices.Thepartsrequiredmicro-machiningwithultra-finetolerances,whichlocalsuppliersstruggledtoachieveefficiently.PartneringwithanOEMCNCserviceinEastAsiaallowedthecompanytobenefitfromspecializedmicro-machiningcapabilitiesandhigh-volumeproductioncapacity.Thissetupreducedthetime-to-marketsignificantlyandensuredconsistentqualityacrossbatches.SuchcollaborationsdemonstratehowOEMCNCservicescanservetheelectronicsindustry’sneedforprecision,scalability,andgeographicflexibility,especiallywhenrapiddeploymentacrossmarketsisessential.

IndustrialmachinerymanufacturersalsoleverageOEMCNCservicesforcomplex,large-scalecomponents.AnAfrican-basedcompanyproducingminingequipmentcollaboratedwithaEuropeanOEMCNCprovidertomanufacturecustomgearsandhousings.Theprojectinvolvedmachiningtoughmaterialswithprecisedimensionstowithstandharshenvironments.TheEuropeansupplier’sadvancedCNCmachinesandqualitycontrolprocessesensuredthepartsmetstrictdurabilitystandards.ThispartnershipunderscoreshowOEMCNCservicescansupportmanufacturinginemergingmarketsbyofferingaccesstohigh-precision,reliablecomponentsfromestablishedmanufacturinghubs,therebyexpandingtheirglobalfootprint.

TheintegrationofdigitaltechnologieshasfurtheramplifiedtheinternationalreachofOEMCNCmachining.Manyprovidersnowutilizecloud-baseddesignsharing,real-timemonitoring,andadvancedCAD/CAMsoftwaretocoordinatemanufacturingacrossborders.AcaseinpointisaJapaneseaerospacepartssupplierthatcollaborateswithNorthAmericanclientsthroughdigitalplatforms,enablingseamlesscommunicationanditerativedesignadjustments.Thisapproachreduceserrors,acceleratesproductioncycles,andfosterstrust,demonstratinghowdigitaltransformationenhancesglobalOEMCNCservicecapabilities.

CostefficiencyremainsakeydriverbehindthewidespreadadoptionofOEMCNCservicesinternationally.Forinstance,aSouthAmericanappliancemanufactureroutsourcedcriticalcomponentstoAsianCNCproviders,reducingproductioncostsbyupto30%comparedtolocaloptions.Thesavingsallowedreinvestmentintoproductinnovationandexpandedmarketreach.Similarly,qualitystandardsandcertifications,suchasISOandTS,ensurethatcostadvantagesdonotcompromiseproductintegrity,makingOEMCNCservicesastrategicchoiceforcompaniesseekingtooptimizetheirglobalsupplychains.

Inadditiontotraditionalmanufacturing,OEMCNCservicessupporttheburgeoningfieldofcustomandsmall-batchproduction.AstartupinAustraliadesignedspecializedmedicaldeviceprototypes,partneringwithaChineseOEMCNCshopforrapidfabrication.Theabilitytoproducesmallquantitiesefficientlyallowedthestartuptotestmultipledesignsanditeratequickly,significantlyshorteningtheirdevelopmentcycle.ThisshowcaseshowOEMCNCservicesfacilitateinnovationandflexibility,especiallyforsmallandmedium-sizedenterpriseslookingtocompeteonaglobalscale.

ThelogisticsandsupplychainconsiderationsarepivotalinexpandingOEMCNCservicesglobally.Companiesincreasinglyrelyonnear-shoreoroff-shorepartnerstoreduceshippingtimesandcosts.Forexample,aEuropeanautomotivesupplierestablishedaregionalCNCmachiningcenterinEasternEuropetoservenearbymarketsmoreswiftlythandistantAsianfacilities.Conversely,somefirmsprefertopartnerwithestablishedOEMprovidersinAsiaforlarge-volume,cost-sensitivecomponentsduetothescaleandinfrastructureadvantages.ThesestrategicchoicesreflecthowOEMCNCservicesadapttomarketdemands,balancingcost,quality,anddeliveryspeedacrossdifferentregions.

Theenvironmentalandsustainabilityaspectsarealsogainingimportance.OEMCNCproviderswithgreenmanufacturingpractices,suchaswastereduction,energy-efficientmachines,andeco-friendlymaterials,appealtoglobalclientsseekingsustainablesupplychains.AnIndian-basedOEMCNCshopadoptedrenewableenergysourcesandoptimizedmachiningprocessestoreducecarbonfootprint,attractinginternationalclientscommittedtoenvironmentalresponsibility.ThistrendindicatesthatglobalOEMCNCservicesarenotonlyaboutreachandcapacitybutalsoaboutaligningwithbroadersustainabilitygoals.

Insummary,OEMCNCmachiningserviceshaveestablishedabroadglobalpresencebyleveragingtechnologicaladvancements,strategicpartnerships,andflexiblemanufacturingsolutions.Theyservediverseindustrieswithvaryingrequirements,fromaerospacetoelectronics,automotivetoindustrialequipment.Theirabilitytoprovidehigh-quality,precisecomponentsacrossbordersreducescosts,shortensleadtimes,andenhancesinnovationforcompaniesworldwide.Asdigitaltoolsandsustainablepracticesbecomemoreintegratedintomanufacturing,theglobalreachofOEMCNCservicesisexpectedtocontinueexpanding,supportingamoreinterconnectedandefficientglobalsupplychain.

1.OEMCNCmachiningservicesenablecompaniestoaccesshigh-precisioncomponentsfromdiverseregions,reducingcostsandleadtimeswhilemaintainingqualitystandards.

2.Strategicpartnershipsandtechnologicalintegrationfacilitateseamlessinternationalcollaboration,allowingforcustomization,rapidprototyping,andscalableproduction.

3.TheadoptionofsustainablemanufacturingpracticesanddigitalplatformsenhancestheglobalcompetitivenessandadaptabilityofOEMCNCserviceproviders,supportingindustriesinvarioussectors.